-

-

-

JRREADY YJQ-W2D Four-indent Hand Crimp Tool

1. Designed according to MIL-C-22520/1-01;

2. Suitable for crimping Deutsch 12#, 16#, 20# round contacts;

3. Suitable for crimping round contacts of MIL standard, Harting, Wain, TE connectors;

4.Wire Crimp Range: 12-26AWG(0.128-3.33mm²);

5. Positioner & crimper integration; screw positioning size designed according to HDT-48-00 crimper; positioner axially adjustable.

Brand: JRREADY | Standard: MIL-C-22520/1-01 (Not QPL) | Model: YJQ-W2D |

Crimp Style: Four-indent Eight-impression | Material: Mould Steel | Selector Numbers: 8 |

Wire Size (AWG/mm²): 12 (3.33)-26 (0.128) | Thru-hole Diameter (mm): Φ5.60 | Dimensions (mm): 247*59*25 |

Internal Number: D6 | Weight (g): 543 | |

| YJQ-W2D is compatible with the M22520/1-01 which is widely used for the crimping of wires and contacts in electronic connectors. | ||

| Model of check tool: G125 (Note: the gage needs to purchase separately) | ||

Features

1. Material of Mould Steel (Good Durability & Good Anti-deformation & Good appearance & Anti-rust)

2. Four-indent Crimp Tool (Crimp tension is 1.3 times that of the hexagonal crimp, more stable & more reliable)

3.8 Selector Numbers (Adjustable crimping ranges in different selector number, more convenient for wider applications)

Crimp Range

CONTACTS:12-20 #

Selector NO. | Intender Working Diameter mm/INCH | |

A(GO) | B(NO GO) | |

1 | 0.71/0.028 | 0.84/0.033 |

2 | 0.81/0.032 | 0.94/0.037 |

3 | 0.91/0.036 | 1.04/0.041 |

4 | 0.99/0.039 | 1.12/0.044 |

5 | 1.14/0.045 | 1.27/0.050 |

6 | 1.32/0.052 | 1.45/0.057 |

7 | 1.50/0.059 | 1.63/0.064 |

8 | 1.73/0.068 | 1.86/0.073 |

The crimping tool adopts curve propulsion mechanism, its applied force transfers through four curves in the head cavity of the right plier handle to the four indenters. The four intenders do the centripetal linear motion, which makes its front-end teeth crimp the contact to complete the crimping process. The cycle controlled precision ratchet assures the consistency of impression and the crimping quality of wires and contacts.

Crimping Steps

Step 1:Get the crimp tool, contact and wire ready

Step 2:Open the crimp tool

Step 3:Put the wire into the crimp hole

Step 4:Adjust the screw to reach the correct crimp position

Step 5:Tighten the lock nut

Step 6:Insert the wire into the contact

Step 7: Place the wire to the correct position

Step 8:Complete crimp operation

Step 9:open the crimp tool again

Step 10:Remove the crimped contact

Applications

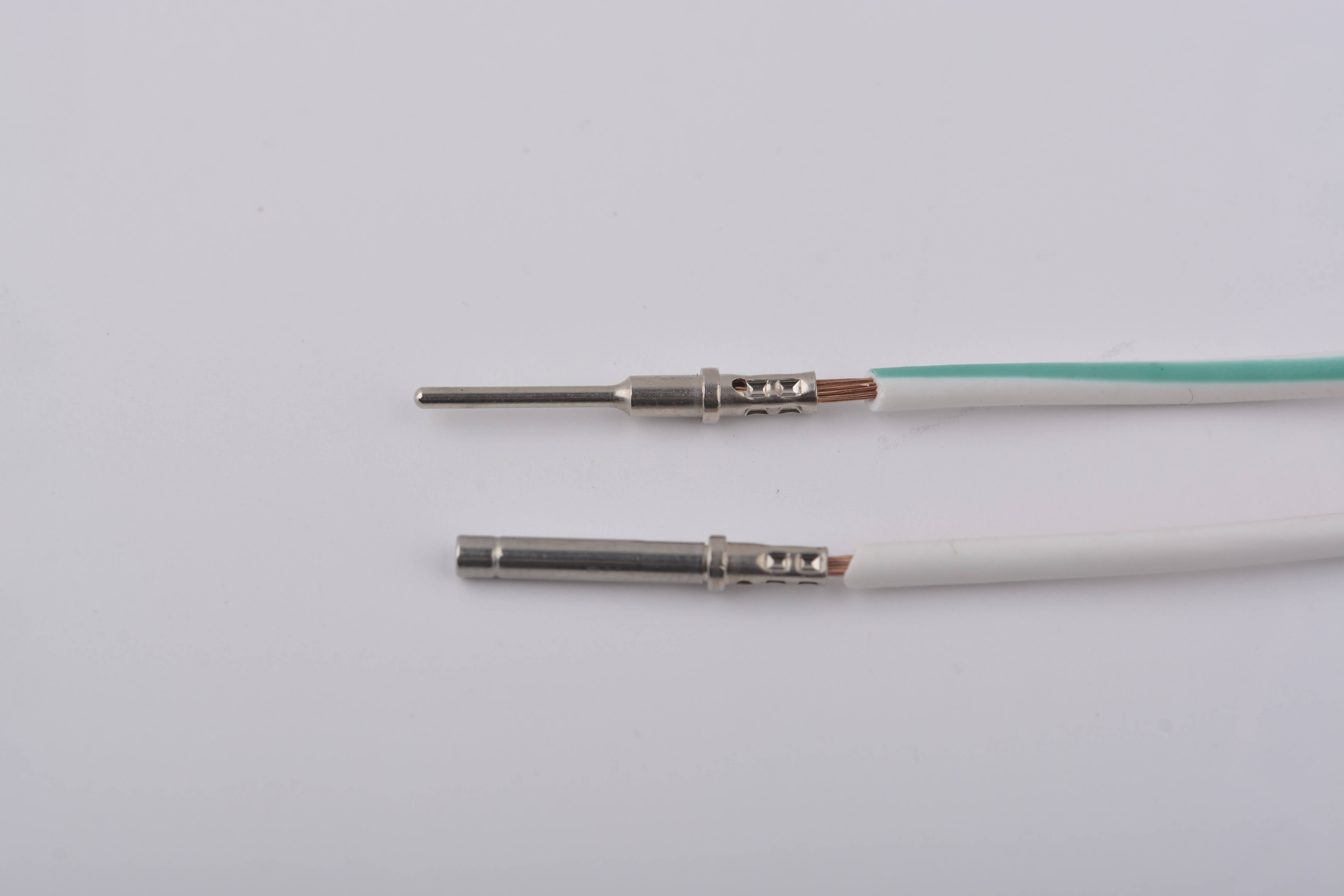

12# Contacts |

16# Contacts |

20# Contacts |

INCREASE 16#, 22# Contacts |

WAIN Contacts |

Amphenol Contacts |

Crimping Instructions

Step 1 : Put the contact |

Step 2 : Insert the wire |

Step 3 : Crimp and open the crimp tool |

Step 4 : Remove the crimped contact |