-

-

-

JRREADY YJQ-801 Eight-indent Hand Crimp Tool

1. A type of miniature hand crimp tool;

2. Eight-indent crimp tool specially designed for crimping twisting pins and wires;

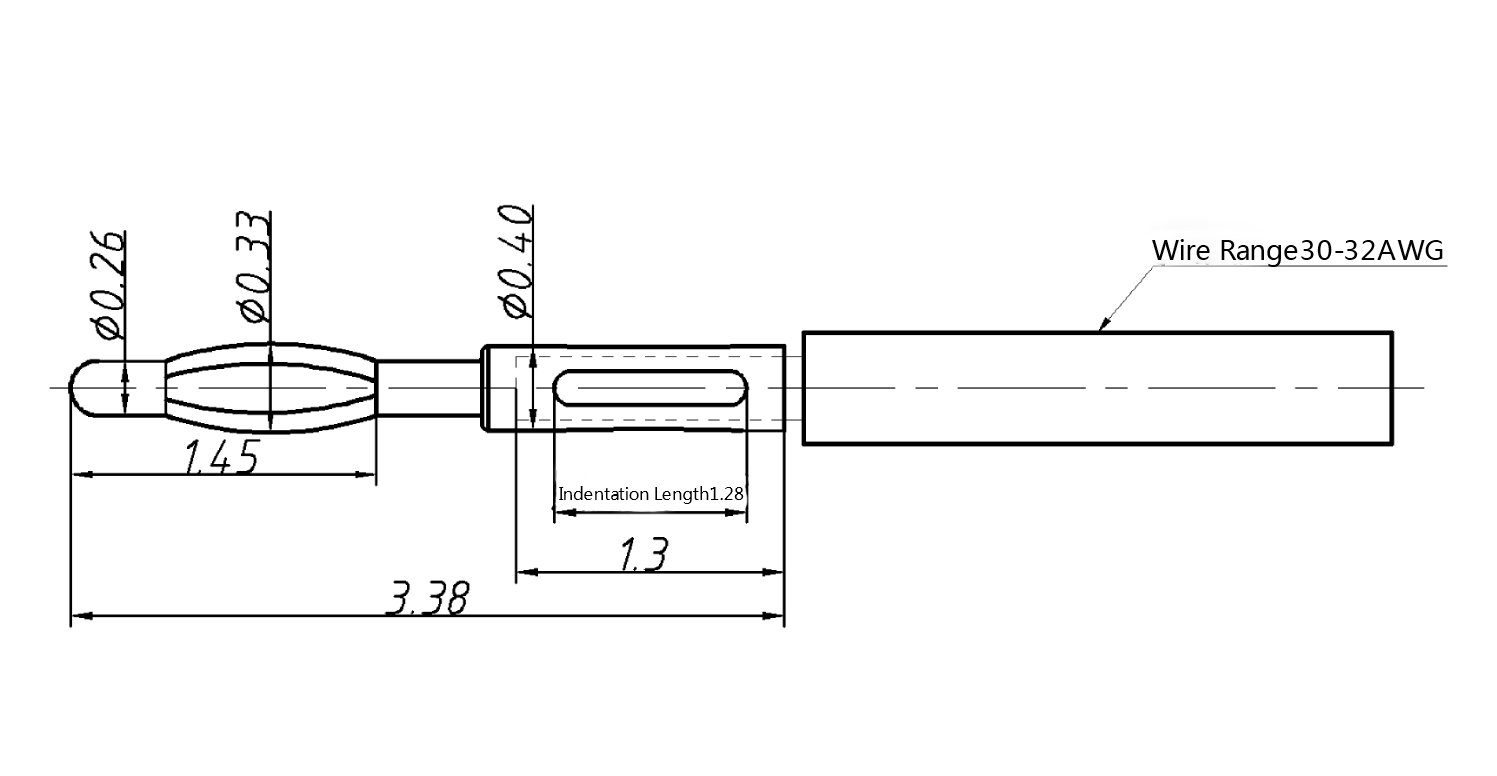

3. Contact Model: MB7.747.5600;

4. Wire Crimp Range: 30-32AWG (0.051-0.032mm²);

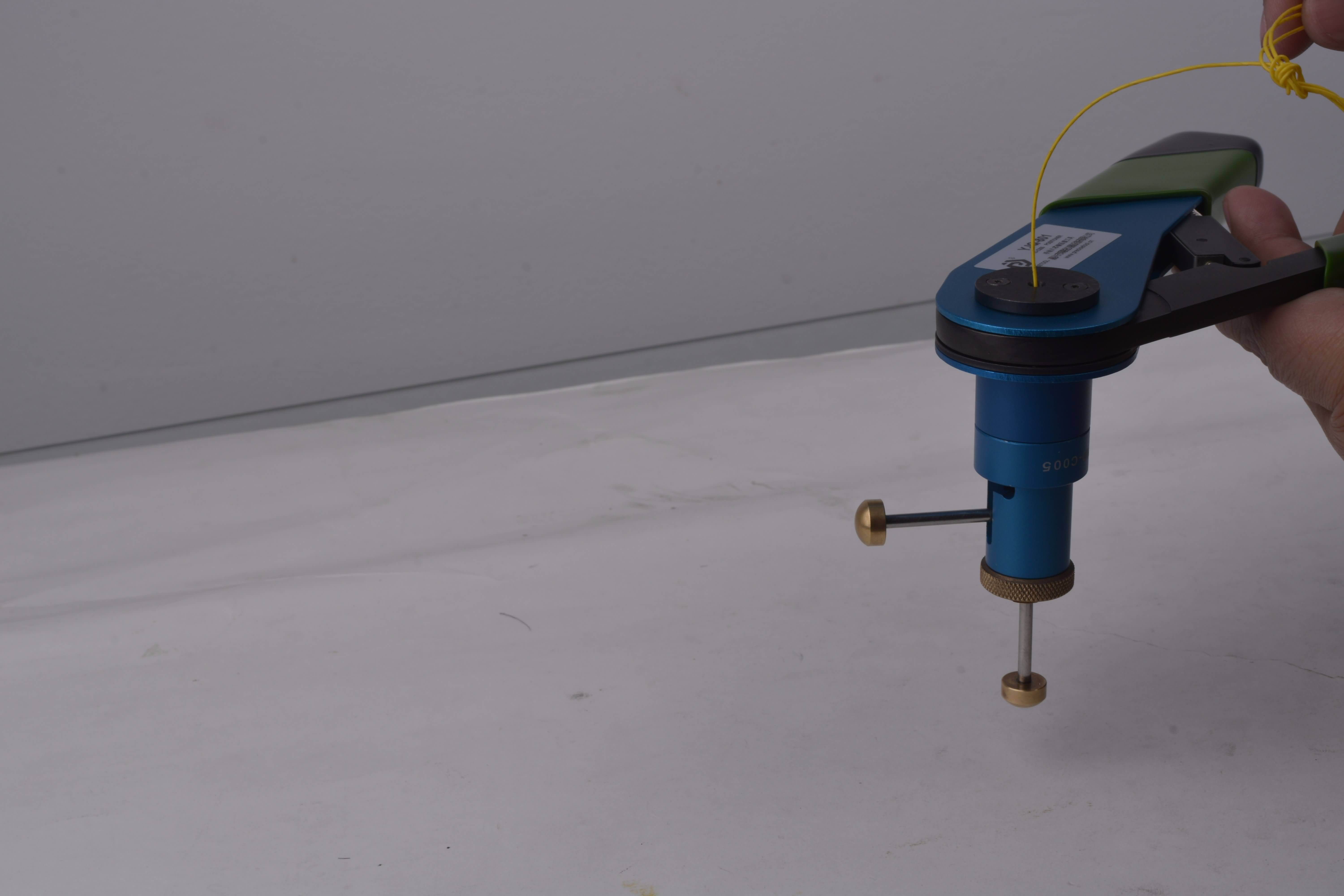

5. Equipped with adjustable lifting positioner HD-C005.

Brand: JRREADY | Standard: / | Model: YJQ-801 |

Crimp Style: Eight-indent Four-impression | Material: Mould Steel | Selector Numbers: 8 |

Wire Size (AWG/mm²): 30 (0.0507)-32 (0.0316) | Thru-hole Diameter (mm): Φ0.45 | Dimensions (mm): 190*59*25 |

Internal Number: D44 | Weight (g): 298 | |

| YJQ-801 is an eight-indent crimp tool specially designed for miniature contacts (Contact Model: MB7. 747.5600). It is used for crimping twisting pins and wires; The crimp tool adopts curve propulsion mechanism, its force transfers through eight curves in the head cavity of the right plier handle to the eight indenters. The first group of four indenters move in place to support and fix the terminal. Then, another group of indenters move in place to complete the wire and terminal crimping. The eight intenders do centripetal linear motion synchronously, which assures the consistency of impression and the crimping quality of wires and contacts.

HD-C005 is an adjustable lifting positioner to locate the twisting pins. | ||

The corresponding relationship between the crimped wires, contacts and selector numbers is shown in the following table:

Contact Model | Crimp OD | Wire Size(AWG) | Selector No. |

MB7.747.5600 Pin | φ0.4 | 30-32 | No. 1 #(0.18-0.32) |

Instructions

The initial state of the positioner |  Step 1: Extending the top rod out of the crimping surface |

Step 2: Put the pin into the positioning hole and insert the wire |  Step 4: Crimp and open the crimp tool |

Schematic Diagram of Crimp Sample