-

-

-

JRready TS-01 Four-indent Pneumatic Crimping Machine

1. Suitable for wiring harness manufacturing industry;

2. Synchronous four-indent crimp machine, fast crimping & one- timeshaping;

3.Designed specially for crimping large size wires. Wire Crimp Range: 12-2AWG(3-35mm²);

4.Continuously adjustable crimping depth,the minimum adjusting range is 0.1 mm.

Brand: JRready | Standard: Customized | Model: TS-01 |

Crimped Shape: Four-indent Eight-impression | Material: Mould Steel | Selector: 2-7mm |

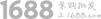

Wire Sizes (AWG/mm²): 12-2 (3.0mm²-35mm²) | Thru-hole Diameter (mm): Φ17.50 | Productivity (pcs/min): 10 |

Dimension (mm): 560*176*450 | Weight (KG): 70 | Air Supply & Working Air Pressure (Bar): 5.5—8.0 |

Internal Number: QT1 | ||

TS-01 is a brand new design, desktop four-indent pneumatic crimping machine, used to crimping large size wires and contacts in electronic connectors. | ||

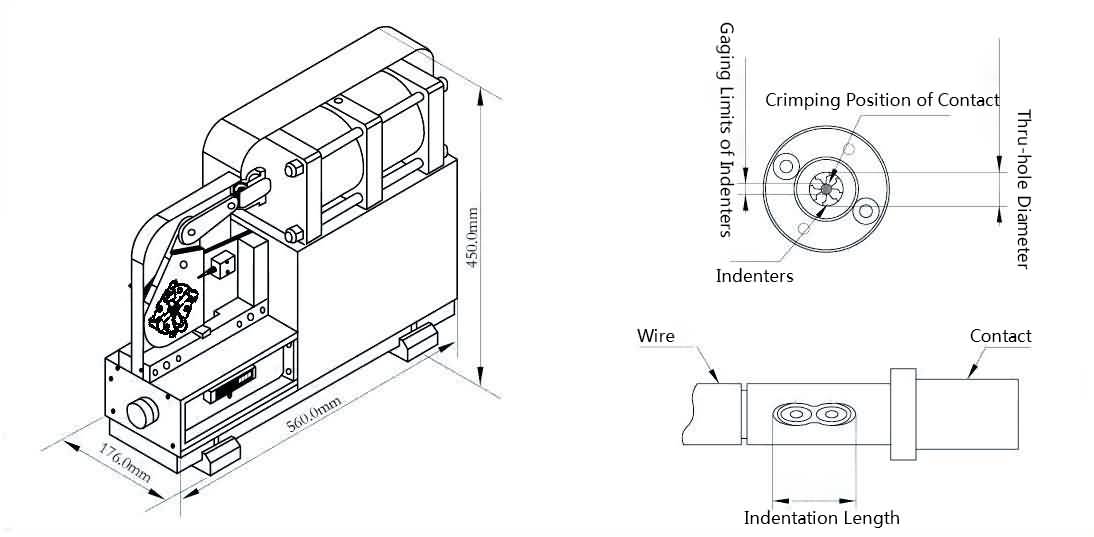

Crimp Principal

The crimping tool adopts curve propulsion mechanism. The output force is given to the crimp handle by the cylinder, and then the four curves of the head of the crimp handle transmit the force to the four indenters. The four indenters do the centripetal linear motion to crimp the contact to complete the crimping process. The synchronized action of four indenters assures the consistency of impression and the crimping quality of wires and contacts.

The selectors of this crimp tool can be continuously adjusted. The adjust range of each selector is 0.1mm, that is, each time the adjustment knob is rotated 1/4 turn, the crimp diameter changes by 0.1mm. This crimp tool is operated by foot value and the working air pressure is controlled and adjusted by the regulating value.

Dimension

Standard Products

Model | Crimp Style | Thru-hole Diameter(mm) | Indenter Working Diameter (mm) | Impression Length(mm) | Wire Size (mm2) |

TS-01 | Four-indent Eight-impression | 17.5 | 2-7 | 4.4 | 3-35 |

TS-02 | Four-indent Eight-impression | 22.4 | 4-9 | 4.6 | 25-70 |

TS-03 | Four-indent Eight-impression | 21.5 | 3-8 | 4.8 | 10-50 |

TS-04 | Four-indent Four-impression | 23.0 | Customized | 1.5 |

Customized Series Products

Model | Crimp Style | Thru-hole Diameter(mm) | Indenter Working Diameter (mm) | Impression Length(mm) | Wire Size (mm2) |

TS-02A | Four-indent Eight-impression | 26 | 8-13 | 9.4 | 70 |

TS-02B | Four-indent Eight-impression | 24 | 6-10 | 9.4 | (50)70 |

TS-02C | Four-indent Eight-impression | 24 | 6-10 | 9.4 | Customized 50 |

TS-02D | Four-indent Four-impression | 26 | 8-13 | 9.4 | Customized 50 |

TS-02E | Four-indent Eight-impression | 23 | 6.5-10.5 | 9.4 | 50, 70 |

TS-03B | Four-indent Eight-impression | 21.5 | 3-8 | 6.4 | 10-50 |

TS-03C | Four-indent Four-impression | 21.5 | 3-8 | 4.8 | Customized 3 |

|  |  |  |

Crimp Instruction

Step 1 | Step 2 | Step 3 | Step 4 |

Step 1: Rotate the adjustment knob to adjust the selectors to the proper position;

Step 2: Use the Go-Nogo gauge to calibrate the indenters closure. When the selector is in the proper position, the green end can pass through;

Step 3: Use the Go-Nogo gauge to calibrate the indenters closure. When the selector is in the proper position, the red end can not pass through;

Step 4: After the selector is adjusted to the right position, insert the contact and the wire and press the foot value to start crimping;

Step 5: After the wire crimping is completed, remove the finished product.