-

-

-

JRready YJQ-X2Q-1.0/1.5 Four-indent Pneumatic Crimping Tool

1. Suitable for the annular crimping of springwire socket. The inside diameter of springwire socket sheath : 1.0mm/1.5mm, the outside diameter: 2.5mm/3.2mm;

2. Four-impression crimping, circumferential distribution, impressions are in the same plane;

3. Adapts UH2, TP2 series of positioners.

Brand: JRready | Standard: / | Model: YJQ-X2Q-1.0/1.5 |

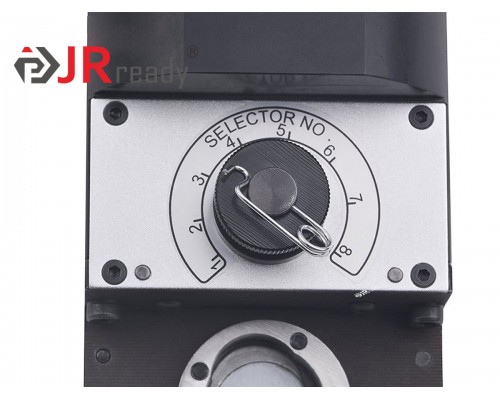

Crimped Shape: Four-indent Four-impression | Material: Mould Steel | Selector Number: 8 |

Dimension (mm): 218.4*59.3*58.5 | Thru-Hole Diameter (mm): Φ5.60 | Productivity (pcs/min): 30-40 |

Internal Number: Q1401 | Weight (g): 1890 | Air Supply & Working Air Pressure (Bar): 5.5-8.3 |

| YJQ-X2Q-1.0/1.5 four-indent pneumatic crimping tool is a customized crimp tool applied to annular crimping of springwire socket. The inside diameter of springwire socket sheath is 1.0/1.5mm, the outside diameter is 2.5/3.2mm; Four-impression crimping, circumferential distribution, impressions are in the same plane. | ||

Features

1. Material of Mould Steel (Good Durability & Good Anti-deformation & Good appearance & Anti-rust)

2. Four-indent Crimp Tool (more stable & more reliable)

3. 8 Selector Numbers (Adjustable crimping ranges in different selector number, more convenient for wider applications)

Crimp Range

This tool is suitable for outer diameter of the sheath 2.5mm and 3.2mm. The selector number is NO.2 and NO.7. Details as follows:

Selector Number | A(GO) | B(NO GO) | Instructions |

NO.1 | <2.1 | ||

NO.2 | 2.10 | 2.20 | 0.03-0.05mm smaller than the NO.3, used for fine-tuning |

NO.3 | Applicable sheath outer diameter 2.5mm | ||

NO.4 | Unavailable | ||

NO.5 | Unavailable | ||

NO.6 | <2.8 | 0.03-0.05mm smaller than the NO.7, used for fine-tuning | |

NO.7 | 2.80 | 2.90 | Applicable sheath outer diameter 3.2mm |

NO.8 | |||

The crimping tool adopts curve propulsion mechanism, its applied force transfers through four curves in the head cavity of the right plier handle to the four indenters. The four intenders do the centripetal linear motion, which makes its front-end teeth crimp the contact to complete the crimping process. The cycle controlled precision ratchet assures the consistency of impression and the crimping quality of wires and contacts.

Picture of the whole set

Applications

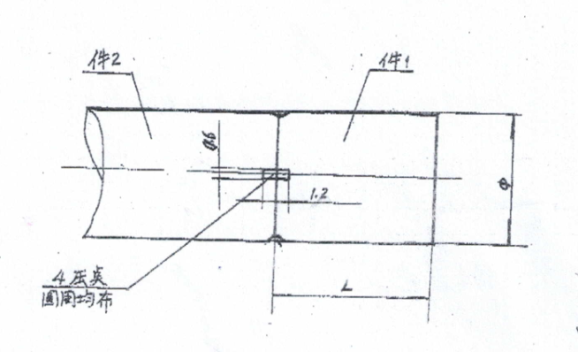

Model | Standard | φ±0.05 | L±0.05 |

YJQ-X2.0-1.0/1.5 | φ1.0 | 2.5 | 2.7-3 |

φ1.5 | 3.2 | 2.7 |